With population levels in Australia projected to soar to approximately 40 million by 2055, investment in critical infrastructure will see a renewed focus from all facets of government over the coming years to ensure that Australia’s transport system can cope with this projected growth.

This transport infrastructure focus has already commenced with the Federal Government recently launching the Infrastructure Investment Program, an initiative designed to deliver a $110 Billion boost to Australia’s transport infrastructure pipeline.

With all levels of government prepared to fast-track transport infrastructure developments, the longevity of these developments become a point of significant focus.

Transport for New South Wales (TfNSW) outline specific pavement design requirements to ensure a consistent approach is undertaken in the construction of the state’s roadway infrastructure developments. This detail is outlined within the ‘Supplement to Ausroads Guide to Pavement Technology’.

This supplement defines four key Typical Pavement Profiles for heavy duty pavements and outlines the different asphalt and subbase construction requirements for each to ensure construction consistency and durability over the projects estimated lifetime.

These are:

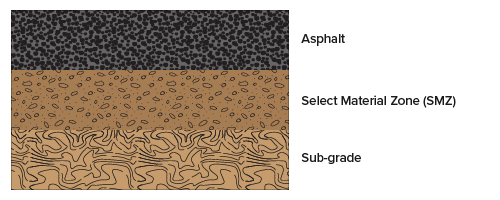

The full-depth asphalt approach includes a 300mm Select Material Zone (SMZ) laid atop of the subgrade with up-to 350mm of asphalt laid on top of the SMZ.

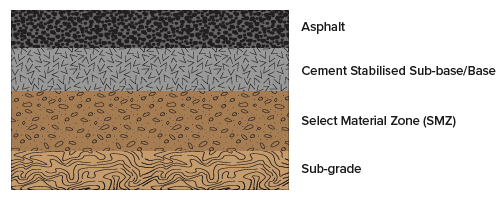

Rather than full asphalt, this approach combines both a layer of asphalt (175mm minimum) and a layer of cement stabilised material (170mm-250mm) atop of the 300mm SMZ.

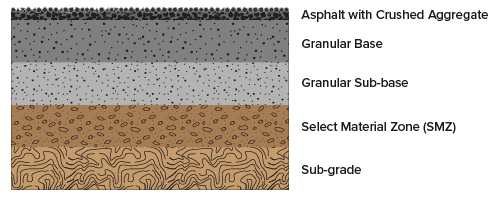

This road base construction technique is regularly found in Australia due to its low-cost application. It consists of a granular sub-base laid atop of the SMZ before the application of at least 200mm of Class One Granular Base. This Class One base is then sprayed with a hot bitumen sealant, followed by a single layer of crushed aggregate to complete the surface. Whilst a cost-effective solution, this approach is susceptible to both weather and load weight restrictions so is not an appropriate solution for all applications.

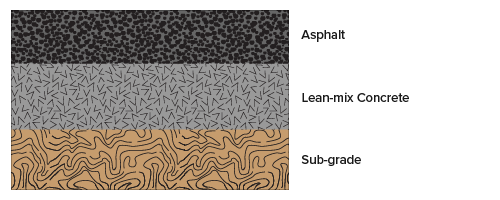

This approach utilises a 150mm-230mm layer of lean-mix concrete laid above the SMZ, topped with a 175mm asphalt top layer.

These four industry-standard construction methods require a range of high-quality asphalt products to facilitate construction.

At Hunter Quarries, we’re able to provide a range of premium asphalt & concrete aggregates, road-bases, sub-bases, Select Material Zones (SMZ’s) and fill products ensuring the quality of your finished transportation infrastructure is of the highest calibre.

We can provide asphalt aggregates in 7mm, 10mm, 14mm, 20mm, and 28mm sizing, concrete aggregates in 10/7mm and 20/14mm as well as Concrete and Asphalt Manufactured Sands. Additionally, we can provide custom TfNSW compliant Gabions and Armour Rocks as well as the range of TfNSW and council compliant fill, select, sub-base and base materials all tested and certified in NATA accredited laboratories.